BUSINESS

Our Business

Transforming All Waste into Valuable Resources.

As a comprehensive recycling company that brings together the technological prowess of the JFE Group, J&T Recycling provides total solutions covering everything from environmental consulting to collection and transportation, intermediate treatment, and recycling in compliance with the Waste Management and Public Cleansing Law. Please feel free to contact us for any waste management needs.

- Comprehensive Solutions Business

- Incineration and Power Generation

- Food Recycling

- Comprehensive Plastic Recycling

- PET Bottle Recycling

- Recycled Plastic Pallets

- Medical Waste Recovery

- Liquid, Sludge and Beverage Waste Recycling

- Solar Panel Recycling

- Confidential Media Treatment

- Solid and Mixed Waste Recycling

- Wooden Waste Recycling

- Kneading & Ash Recycling

- Dry Cell and Battery Recycling

- Polychlorinated Biphenyl (PCB) Treatment

- Home Appliance Recycling

- Collection, Transportation and Freight Services

Comprehensive Solutions Business

Selection of optimal disposal methods based on waste characteristics

Handling non-core operations to help clients focus on their core business

Comprehensive Solutions Business

We provide comprehensive support for non-core business, enabling companies to focus on their core business activities. Our expert staff covers everything from organizing waste collection and transportation, proper processing, and recycling right through to ensuring compliance with laws and regulations. This enables our clients to minimize their burden on the environment while running their business efficiently. Our highly reliable services help our clients to realize a sustainable business.

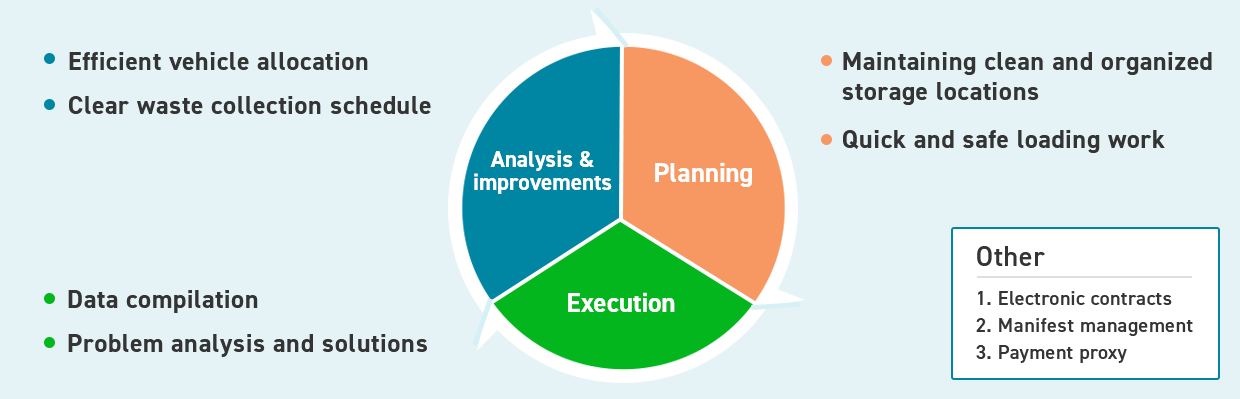

Features of Comprehensive Solutions Business

-

Proposing Optimal Waste Treatment Method

J&T Recycling offers customized waste treatment solutions to our clients' specific needs. Those proposals can be most suitable methods with efficient and environmentally conscious method with specialized external contractors.

-

Nationwide Coverage

Leveraging its nationwide network, J&T Recycling can offer the optimal industrial waste disposal service to its customers anywhere in Japan. Whether it be the countryside or a major city, we customize consistent, high-quality services and responds flexibly to the unique needs of each region.

-

On-Site Staff and Flexible Response

An unexpected incident could occur in all phases related to waste management, from planning and execution to analysis, improvement, and disposal. By having staff stationed on our customers’ premises, J&T Recycling can respond quickly to problems and execute work to a high standard as and when necessary.

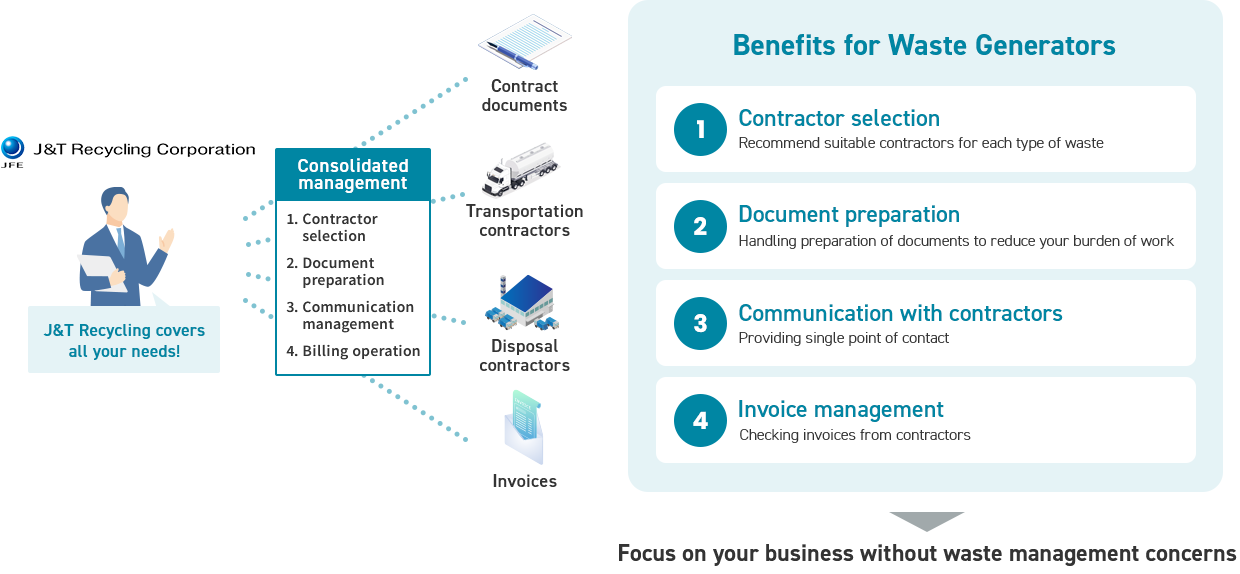

Benefits of Comprehensive Solutions Business

Comprehensive On-Site Management

Solutions Business Details

-

①Vendor Selection

J&T Recycling selects the most suitable waste management partners from our network based on your specific waste handling requirements. *All potential partners undergo site inspections and compliance checks to ensure they meet our strict standards.

-

②Documentation Management

Handling all required documentation, including:

-Industrial waste management contracts

-Operation plans

-Work reports

All documents are processed electronically, reducing paper usage and stamp duty costs. -

③Communication Management

By serving as your single point of contact for all waste management vendors:

-Allow you to focus on your core business

-Provide immediate response to any issues

-Ensure proper communication with relevant parties

-Implement swift countermeasures when needed -

④Billing Operations

Managing all financial aspects, including:

-Invoice issuance to clients

-Payment processing for collection and disposal contractors

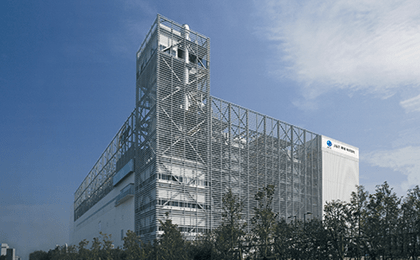

Incineration and Power Generation

With one of the largest networks in the Tokyo metropolitan area, we handle a wide variety of waste to help form a recycling-based society. We generate electric power by using waste heat produced during the incinerating process, and collect the ash to reuse it as raw materials for steel or civil engineering materials. We also undertake thorough measures against exhaust gas, removing dioxins and nitrogen oxides by passing the fumes through a gas cooler, dust collector, and denitration reaction tower.

-

Yokohama Eco Clean (Kiln/stoker type furnace)

Treatment capacity:219.9 t/day

Infectious waste treatment capacity:26.9 t/day

-

Kawasaki Eco Clean (Kiln/stoker type furnace)

Treatment capacity:241.7 t/day

Spray can crushing capacity:6.5 t/day

Infectious waste treatment capacity:20 t/day

-

Tokyo Waterfront Eco Clean

(Fluidized bed gasification and melting furnace)Treatment capacity:550 t/day (275 t/day x 2 systems)

-

Kurashiki Incineration Plant (Kiln/stoker type furnace)

Treatment capacity:94.8 t/day

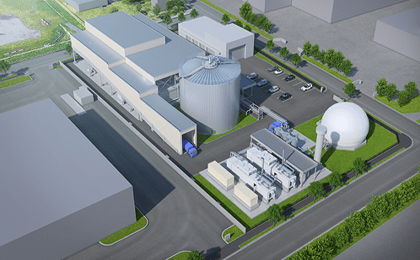

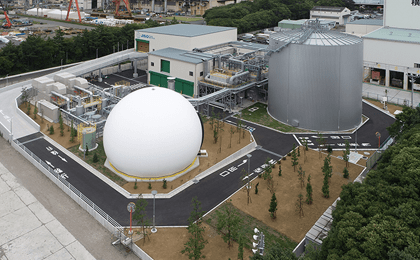

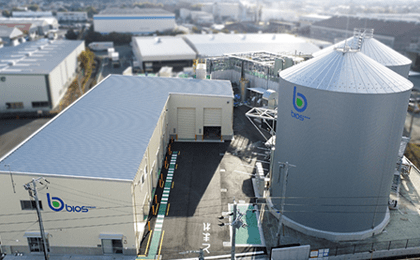

Food Recycling

Through advanced methane fermentation technology, we process mixed food waste, including packaging and wooden utensils, creating a dual-benefit recycling system that produces both renewable energy and fertilizer.

-

SAPPORO BIO FOOD RECYCLING CORPORATION

Treatment capacity:100 t/day

-

Tohoku Bio Food Recycle Co., Ltd.

Treatment capacity:40 t/day

-

Chiba Biogas Center

Treatment capacity:65 t/day

-

J Bio Food Recycle Corporation

Treatment capacity:120 t/day

-

Bios Komaki Co., Ltd.

Treatment capacity:120 t/day

-

FUKUOKA Bio Food Recycling Co., Ltd.

Treatment capacity:100 t/day

Comprehensive Plastic Recycling

Implementation of integrated plastic waste recycling solutions.

Contributing to CO2 reduction and landfill waste elimination.

PET Bottle Recycling

Used PET bottles are collected from various sources, including municipal collections contracted through The Japan Containers and Packaging Recycling Association, retail stores, commercial facilities, and vending machine locations. Through multiple processing steps - crushing, sorting, washing, dewatering, and drying - these materials are converted into recycled PET flakes. This horizontal recycling system (Bottle-to-Bottle) enables used PET bottles to be transformed into new PET bottles, contributing to resource circulation and CO2 emissions reduction.

-

Kawasaki PET Bottle Recycling Plant

Treatment capacity:15,000 t/year

Producing flakes:Recycling PET bottles into raw materials for PET bottle or other products

-

Kyoei J&T Recycling Corporation

Treatment capacity:60,000 t/year

Target:Used PET bottles

Recycled Plastic Pallets

While wooden pallets have traditionally dominated the logistics industry as cargo platforms, plastic pallets are gaining popularity due to their pest resistance and durability. Leveraging established material procurement channels and technical expertise developed through various plastic recycling operations, used plastics are transformed into valuable resources for manufacturing. These environmentally friendly recycled plastic pallets are manufactured and distributed using recycled materials as raw materials.

Medical Waste Recovery

Medical waste from healthcare facilities and research institutions undergoes two types of recycling processes:material recycling for resource recovery and thermal recycling through waste heat power generation. Advanced technologies and strict control systems are implemented to ensure safe processing of high-infection-risk waste. This comprehensive approach contributes to sustainable society through reduced environmental impact and effective resource utilization.

-

Tokyo Waterfront Eco Clean (Vertical Furnace)

Treatment capacity:maximum of 100 t/day (50 t × 2 systems)

※One of the largest medical waste treatment facility in Japan

-

Yokohama Eco Clean (Kiln/stoker type furnace)

Infectious waste treatment capacity:26.9 t/day

-

Kawasaki Eco Clean (Kiln/stoker type furnace)

Infectious waste treatment capacity:20 t/day

Liquid, Sludge and Beverage Waste Recycling

The high-concentration liquid waste treatment system accommodates a wide variety of liquid waste and sludge types. Environmentally conscious treatment processes are selected according to each specific waste type, ensuring safe detoxification. The system promotes environmental conservation through various methods, including resource recovery from dewatered cake and ammonia water recycling.

-

Chemical Works

Treatment capacity:Neutralization:1761.5 m³/day, Insolubilization:145.2 m³/day, Reduction:87.3 m³/day, Crushing:46.7 t/day

Solar Panel Recycling

Our solar panel recycling factory sorts and crushes solar panels made of composite materials until they become recyclable materials to contribute to the effective use of resources.

-

Solar Panel Recycling Factory

Treatment capacity:4.8 t/day *240 panels/day in 60 cell size

Treatment methods:sorting and crushing

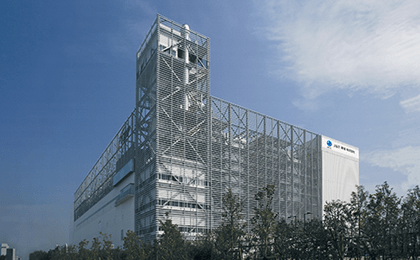

Confidential Media Treatment

The disposal of confidential media employs an automated warehouse system that transfers sealed containers directly to the incinerator, eliminating information leakage risks. The incineration process incorporates waste heat recovery for power generation, combining security with environmental sustainability. This comprehensive security system safeguards clients' information while maintaining environmental responsibility.

-

Tokyo Waterfront Eco Clean (Vertical Furnace)

Treatment capacity:maximum of 100 t/day (50 t × 2 systems)

Solid and Mixed Waste Recycling

Integrated processing capabilities from advanced sorting of mixed waste through to recycling.

Handles a wide range of mixed materials including LED lighting and disaster debris, with sophisticated sorting of metal-containing machinery, achieving a remarkable 96% recycling rate.

-

Kanazawa Recycling Plant (Kanazawa Ward, Yokohama City)

Treatment capacity:3,200 t/year

Features:sorting and recycling mixed waste

Wooden Waste Recycling

Wood waste from construction sites, sawmills, and furniture manufacturers is processed for reuse. These materials are transformed into wood chips, biomass fuel, and recycled wood products, creating new energy resources and products. This recycling process contributes to sustainable society by reducing environmental impact and promoting effective resource utilization, while also preventing illegal dumping and protecting local environments.

-

Kurashiki Recycling Plant

Treatment capacity:

Crushing (industrial, municipal) 110 t/day (8h)

Carbonization (industrial, municipal) 65 t/day (24h), 27 t/day (24h)

Combustion (biomass boiler) 27 t/day (24h)

Kneading & Ash Recycling

Industrial waste containing hazardous substances, such as dust, sludge, and incineration ash from incinerators, wastewater treatment facilities, and various manufacturing plants, undergoes detoxification through mixing with other materials and chemical treatment. This process reduces leaching values below landfill standards for final disposal.

-

Kure Recycling Plant

Treatment capacity:66,000 t/year

Features:A specialized facility for detoxifying hazardous substances in sludge and dust through mixing and stabilization treatment.

・Detoxification of specially controlled industrial waste

・Recycling of industrial waste (including fly ash from biomass power plants) into recycled soil materials

Dry Cell and Battery Recycling

Dry Cell Battery:Iron components recovered for steel manufacturing, Zinc extracted for use in refineries

Rechargeable Battery:Recovery of battery fluid and metals

-

Chemical Works

Treatment capacity:80 t/year

Polychlorinated Biphenyl (PCB) Treatment

PCBs are hazardous substances that pose risks to both the environment and human health, requiring safe and reliable disposal methods. We provide specialized knowledge and technical expertise to support companies and local governments in managing waste in compliance with regulations. Additionally, we offer consulting services for treatment facility operations and waste collection/transportation to promote sustainable environmental protection.

Home Appliance Recycling

Motors and heat exchangers sorted through the home appliance recycling operations of JFE Urban Recycle Corporation (our group company) are crushed and sorted at our appliance processing facility to recover individual materials such as iron, aluminum, and copper for recycling.

-

JFE Urban Recycle Corporation

Treatment capacity:321.82 t/day

Features:Recycling based on Act on Recycling of Specified Kinds of Home Appliance (Home Appliance Recycling Law)

Collection, Transportation and Freight Services

A diverse fleet of vehicles enables safe and efficient transportation services tailored to various cargo types. The comprehensive fleet management system provides complete monitoring of all vehicles, including real-time location tracking and vehicle status, while promoting eco-friendly driving practices. The service accommodates a wide range of transportation needs.